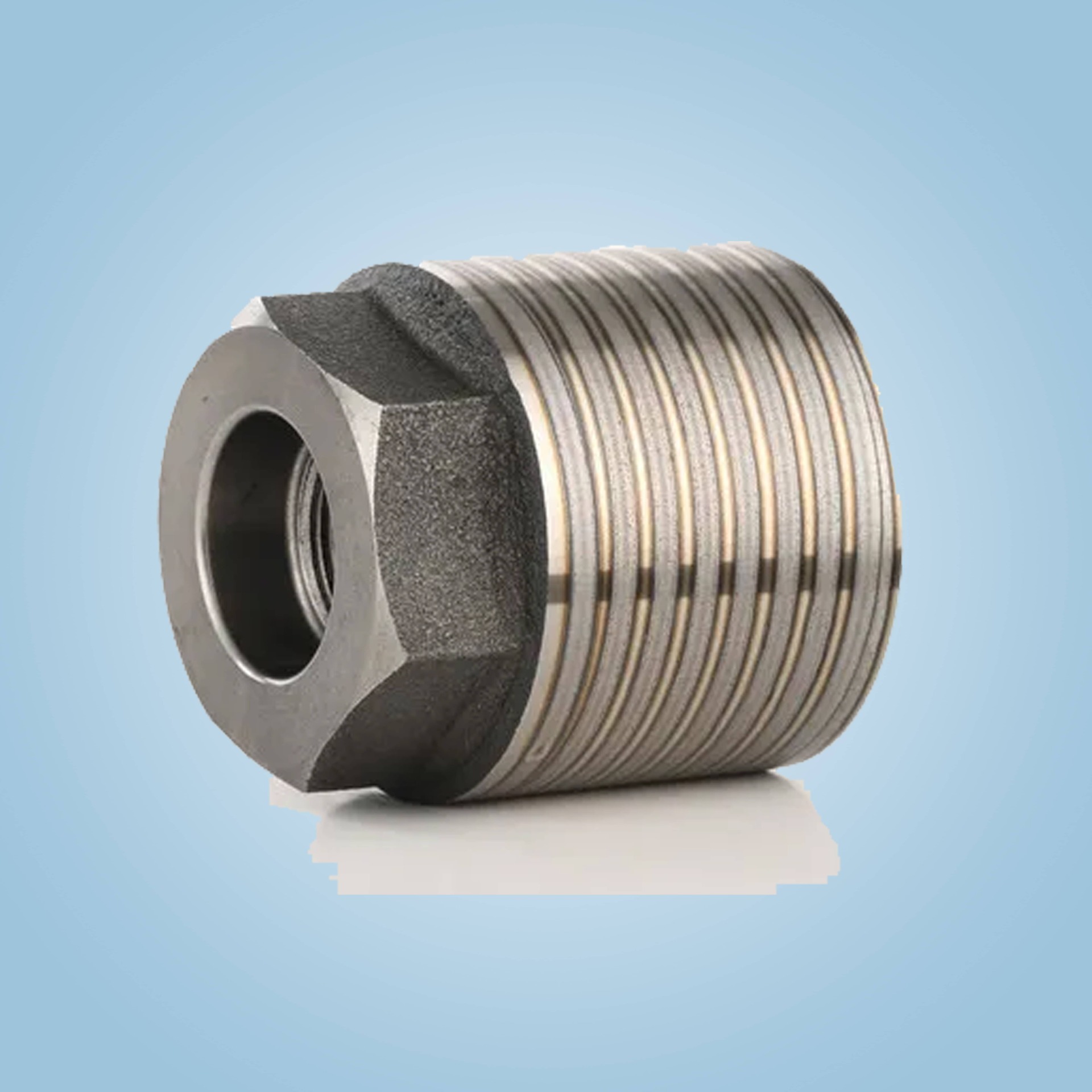

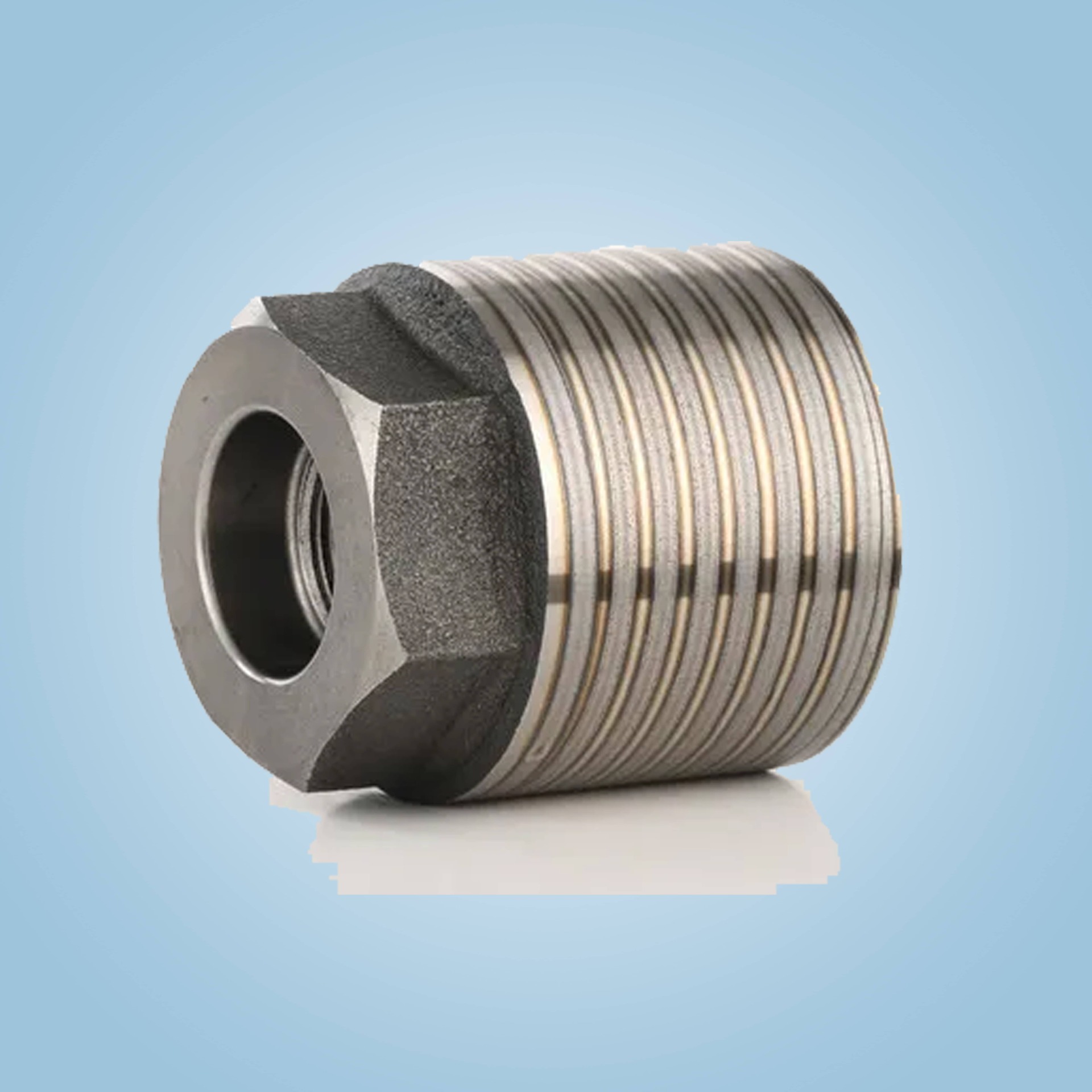

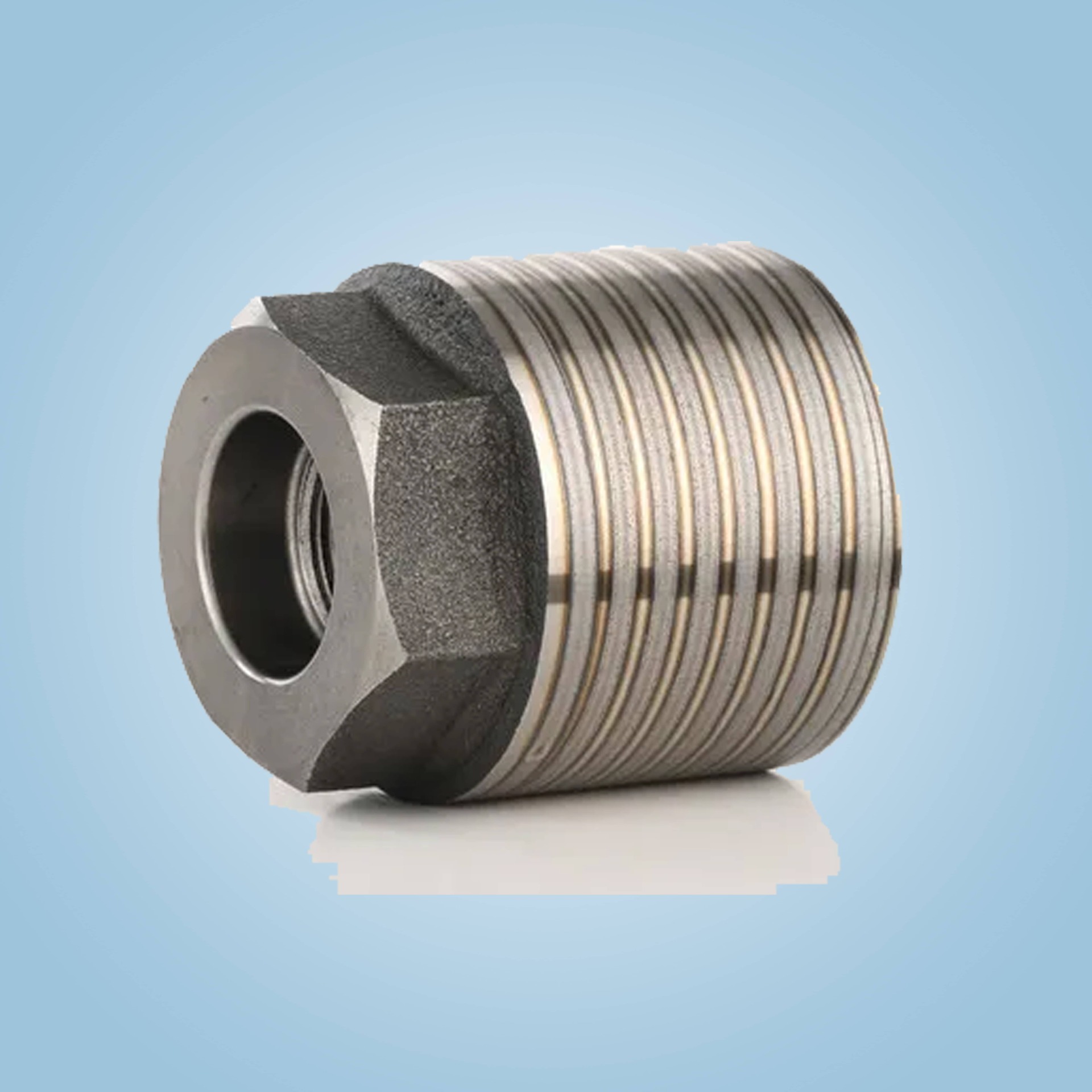

Laser Ceramic Plunger Tip

Laser Ceramic Plunger Tip

Laser Ceramic Plunger Tip

Laser Ceramic Plunger Tip

Laser Ceramic Plunger Tips are specialized components used in die casting processes.

They are designed to improve the efficiency, durability, and overall performance of the die casting machine. The tip is made of a

steel substrate, which is then coated with a ceramic layer using a laser process. This unique manufacturing process creates a surface with a high degree of hardness and wear resistance.